AIR FILTERS EXPLAINED

Media Air Filters Explained

Air generally contains a great deal of contaminating material which may be in the form of solid or liquid particles such as mineral dusts, particles of carbon, and tar in fuel smoke. The contaminant may also be gaseous, for example sulphur dioxide from the combustion of sulphur-containing coal.

The factors that determine the selection of an air filter for a certain duty are:

(1) The size, nature and concentration of the contamination to be removed.

(2) The percentage of this contamination to be removed both as regards size and quantity.

The Nature and Concentration of Atmospheric Dust

Atmospheric dust is a mixture of many kinds of solid and liquid material. Some of the substances present are natural, and others are produced by the activities of man.

Among the natural contaminants are earth, sand, vegetable matter, mould spores, bacteria, viruses, and pollens.

The man-made materials include carbon and tar from smoke, and a wide range of industrial dusts.

The particles of atmospheric dust vary in shape from simple spheres to chain-like aggregates and to star-like and needle-like forms. This range of shapes makes it impossible to express the size of a dust particle by a single measurement. When a dust particle diameter is given, it must be clearly understood that this is not a real measurement, it is an equivalent size, which bears an average relationship to the real dimensions of the irregular particles.

The size of dust particles in the atmosphere is usually expressed as equivalent diameters in microns. (NOTE: 25,000 microns~1 inch.)

The smallest particle that can be seen by the naked eye under good conditions is about 10 microns. Dust of over 10 microns diameter usually settles, as on furniture, while dust smaller than 10 microns tends to remain suspended in the air, and gradually dirties all surfaces including walls and ceilings with which it comes in contact.

The sizes of typical atmospheric dust contaminants.

A typical size distribution of atmospheric dust

| Particle diameter | Percentage by number | Percentage by weight | |||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| Note that 96% of the total number of particles in the air are less than 1 micron in diameter and account for only 17% of the total dust weight. | |||||||||||||||||||||||||||||||||||||

It can be seen that 95% by weight of the airborne contaminants are particles of size range 0.5 to 10 microns. There are, however, a large number of particles smaller than 0.5 microns, which represent only 5% of the weight of the air burden.

A normal city atmosphere dust might contain around 45% (by weight) of smoke carbon, 40% of mineral dust derived from roads and concrete, 37% of coal, 3% of fibrous material derived from cloth, and the remainder miscellaneous including bacteria and spores.

Why Filter Air?

A concentration of 2 grains of dust per 1,000 cu.ft. of air does not sound very much. Consider, however, a mechanically ventilated office building, receiving 60,000 cu.ft. of input air per minute, for ten hours each day. Each day this air will deliver 10 pounds of dirt— usually about half soot and carbon—into the building, and spread this dirt efficiently on walls, ceilings, floors, furniture, and occupants. Such an amount of dust is unsightly and may be injurious to health. The mineral content of the dust, which is mainly silica, is extremely abrasive and will damage fine machinery. Overall, the dust causes increased costs in housekeeping and in machine wear, and may cause damage to health.

In other cases there may be special reasons for excluding dust. Some industrial processes, notably food handling, require very clean air to exclude dirt or infection. Persons suffering from allergies require air from which pollen has been removed. Telephone exchanges will not function if dust finds its way into the switching equipment.

These, then, are the arguments for filtering air. To sum up, clean air is more health-giving and also saves money both in housekeeping costs and in other ways. Properly designed air filters can clean dusty air.

How Air Filters Work

Most people understand by “filtration” the removal of solid particles from a fluid, liquid, or gas—as by a sieve or a strainer. This involves passing the fluid through many small holes. The particles larger than the holes are caught and those smaller than the holes pass through. The particles that are caught remain on the surface of the strainer.

This is not what happens in practical air filters.

No air filters even the superfine glass paper type, really work as strainers.

An air filter consists of a web of fine fibres, deep in comparison with particle size. The web must be sufficiently dense to force any particle attempting to pass through it to follow a zigzag course.

The particles, which hit the fibres on their passage through the filter medium, are caught and held by the fibres by one or more of several mechanisms.

The fibres may be coated with an adhesive.

The filter may be so constructed that the fibres hold a static electric charge, which attracts the dust particles.

Very small particles are held by a physical attraction known as Van der Waals force.

As there are several different capture mechanisms at work a filter seldom shows the same efficiency for particles of every size.

Generally speaking:

- Loose thick filters of relatively coarse fibre are most effective for the capture of particles 1-10 microns in diameter. Their effectiveness depends on the physical and chemical nature of the dust, e.g. density, tackiness, water absorbent. Very fine dust and very large heavy particles may penetrate.

- Thinner filters made from fine fibres tend to be more efficient with fine dusts. They will still collect medium to coarse dust, but may block up too soon to be economic on these materials.

- Adhesive coated filters are frequently but not always more efficient than dry filters.

- In dry filters (i.e. not adhesive coated) the chemical nature of the fibre is important. A few synthetic fibre-forming polymers have the property of holding an electrostatic charge in service and this charge effectively traps all but the very largest and smallest particles. The fibres tend to become electrified by friction, as the air passes over them. This effect has been studied extensively and has been shown to account for some of the largest differences in efficiency between filters made of different fibre materials.

Rating of Air Filters

In the design of an air filter installation and the selection of a filter medium, various test values are used. The most important test characteristics are efficiency, dust holding capacity, face velocity, and pressure drop.

1. Efficiency

The efficiency of an air filter is measured by its ability to arrest the passage of and hold airborne particles.

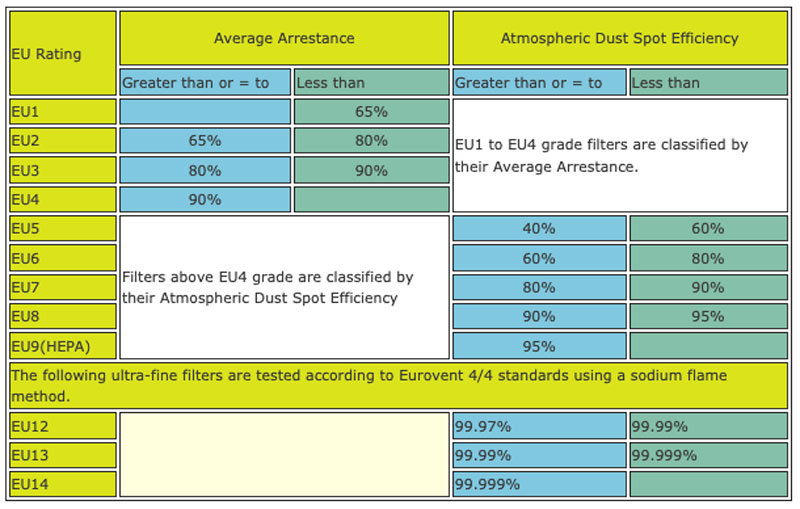

Performance of the filter enables it to be classified to an International standard, the “Eurovent 4/5 Grading”. This classification is also known as the EU rating of the filter and can be in the range EU1 – EU14. (EU1 being the worst performer and EU14 the best).

The most useful and usual definition of efficiency is the ratio of the amount of dust retained by the filter to the amount of dust entering it. The efficiency value obtained varies with the method by which the amount of dust retained by the filter is measured. There are two main techniques used:

Gravimetric, where the ratio of dust collected to dust fed is based on weight measurements,

Discoloration, where the light obstruction or soiling ratio for the clean and dirty air is compared.

Unfortunately values for a given air contaminant with the above two tests do not give results which are directly comparable. It is important, therefore, to check the basis of efficiency when comparing figures for the different filter media.

- Gravimetric (Average Arrestance) Tests These tests assess efficiency by feeding a known weight of standardised dust at a controlled rate to the filter element and either weighing the retained dust on the filter or collecting and weighing the amount of dust passing through the filter.

EU1 – EU4 filter classifications are determined by Gravimetric Tests. The result, expressed as a percentage of the original weight of dust, is called the “Average Arrestance”.

These results can look impressive, for example to attain an EU4 classification a filter media must have an Average Arrestance of over 90%. However this is 90% by weight and, as mentioned earlier, the majority of airborne pollutants (especially the more harmful ones) are so small that they make up only a tiny proportion of the total weight of atmospheric dust.

Typically most of a household dust’s weight is made up of particles measuring 0.2 microns or more in diameter. This leaves a whole host of smaller particles including harmful bacteria and viruses. Which an EU4 filter will do nothing to stop.

Understanding the importance of particulate size is vital when choosing an air filter – click here for more information.

- Discoloration (Atmospheric Dust Spot) Tests These tests are generally used to state the performance of high efficiency filters with submicron particles. The efficiency value is based on the relative discolouring power of the dirty and filtered air.

Finer filters (EU5 and above) are classified according to the results of Discoloration tests.

The test for this involves passing air through the filter and onto a white medium, which any impurities left in the air will stain. A control sample is passed directly onto the white medium without filtration, the control sample is taken from the same source as the test sample and is of the same size. The stains left by the two samples are compared using a spectrometer and the results are expressed as a percentage.

This is known as the “Average Atmospheric Dust Spot Efficiency” and can be considered to be the percentage of the total number of particles that the filter will arrest and hold.

2. Dust Holding Capacity

The dust holding capacity is a measure of the life of the filter. It is usually defined as the weight of dust per square foot which a filter will hold before the pressure drop across the filter reaches a given level at a given air face velocity. As mentioned earlier, the value is dependent on the nature of contamination in the air.

Velocity affects dust holding capacity. Lower velocities than those rated for the filter generally give higher dust holding capacity.

3. Face Velocity and Pressure Drop

These values determine the area of filter required to clean a given flow of air, and the fan power required to pump the air through the filter. Pressure drop is also related to the dust holding capacity because the pressure drop across the filter for a given face velocity increases as the filter becomes full of dirt. It is to be noted that in practical filter construction the face velocity of a filter may not be the same as the velocity of air passing through the media.

Face velocity and air pressure drop of a medium are recommended by the manufacturers.

Users should attempt to operate the filters at these levels.

4. Filter Life

The life of a filter depends on the rate at which air passes through it; on the dust content of the air; and on the dust-holding capacity and efficiency of the filter. Other things being equal a filter of high dust holding capacity, low face velocity and low efficiency will have the longest service life.

CONTACT US.

Email: info@avonelectric.co.nz

Products are New Zealand made by Avon Electric Ltd.

Ph: 03 381-5595 - Fax: 03 381-5596